Design and System Implementation Considerations for High-Temperature Distributed Engine Control

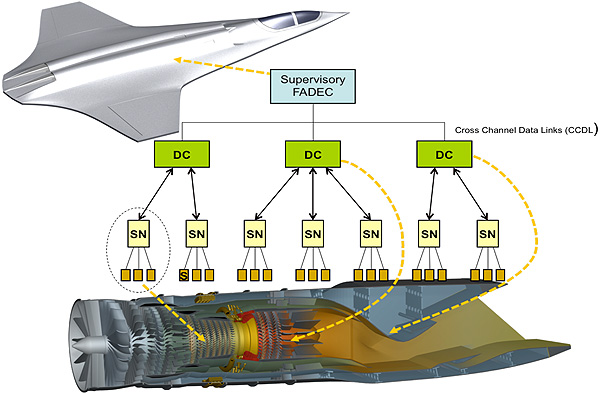

The currently pervasive centralized engine control system architecture for turbine engines consists of a Full Authority Digital Electronic Control (FADEC) module that is hard-wired to sensors and actuators. As a result, new control and sensing technology is slowly adopted within aircraft engines, and when these adoptions are made the overhaul cost is high. Additionally, the FADEC is often unable to pinpoint sensor, actuator, and engine component faults, and the FADEC is required to reside in a cool area of the engine such as the fan case, far away from most sensors and actuators. Design challenges and open questions associated with evolving turbine engine control system architectures from centralized to distributed so that turbine engine control and health monitoring technologies can evolve more rapidly and maintenance costs and wiring weight may be reduced. Methods for incorporating, within extreme temperature environments, the data bus interface, processing, and signal conditioning required to successfully implement a distributed engine control framework in general, and data concentrator specifically, are being considered. Also, we discuss ideas for data concentrator signal processing and communication along the engine control system's data bus.

Considerations for Certifying a Distributed Engine Control

Different from the Norm

|

|

Must Be As Good As Current Architecture

Implementation of Distributed Engine Controls with Smart Sensors