Requirements/Capabilities/Milestones

Physical Drivers for Smart Sensors I Actuators I Distributed Control

System Designs

- Thermal Environment

- Externals Packaging

- Rapid Reconfiguration / Upgradability

- Generic Physical / Functional Interface

- Environmental Requirements

- Certification Impact

- Integration Testing

- Developing Standards

- Financial Responsibility

Focus on Near-Term Applications

- Concentrate on commercial applications with production volumes

- Design for maximum leveraging though multiple applications

Externals Packaging

- Need to integrate electronics onto or within existing hardware

- Minimize unique hardware

- Adding new/extra mounting hardware drives cost, weight in the wrong direction

Environmental Requirements

- Design for existing ambient temperatures and vibration environments

- Don't drive cost/complexity into the DCM to withstand unrealistic margins

- Focus on actual engine environments, not 00160/810 generic requirements

- Design electronics to withstand existing hardware thermal conditions

- Recognize limitations of typical industry materials

- Aluminums (300F/149C), Elastomers (350F/177F)

Certification Impact, Changes to Testing

- Allow certification at modular level

- Require system level certification using black box approach to testing

- Allow flexible system expansion/contraction without recert. required

Integration testing

- System integration testing paradigms will shift

- System integration tasks will shift one layer down the food chain

- AS/OS boundaries may drive testing location, integration responsibilities

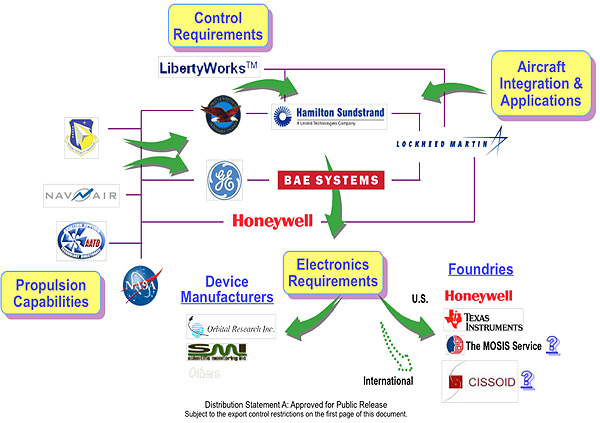

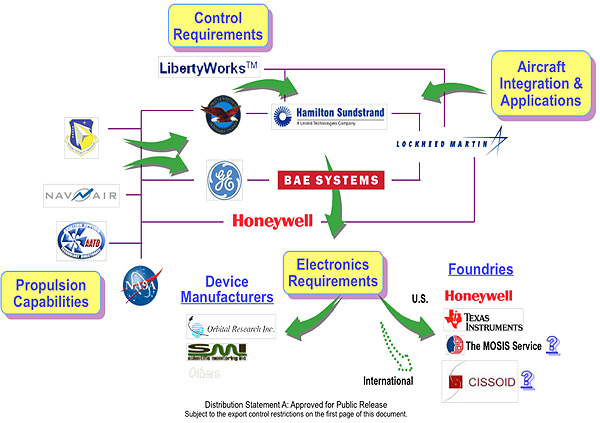

DECWG® Collaboration on Industry-Wide High Temp Electronics Requirements